Non-cellulosic or synthetic fibers

Nylon

Nylon is a strong, lightweight fiber, but it melts easily at high temperatures. It is also a smooth fibre, which means dirt cannot cling easily to its surface. It has very low absorbency so dries quickly and doesn’t need ironing. Nylon is made from non-renewable resources and is non-biodegradable. During the Second World War silk supplies from Japan were cut off, so the US government redirected the use of nylon in the manufacture of hosiery and lingerie to parachutes and tents for the military

Acrylic

DuPont developed acrylic in the 1940s. It has the look and handle of wool, but pilling can be a problem. It is non-allergenic, easy to wash, but sensitive to heat and melts under high temperatures.

Polyester

Polyester is a strong, crease-resistant fiber developed in 1941 by ICI. It is the most widely used synthetic fiber and is most commonly found in blends where it is used to reduce creasing, softening the handle of the cloth and adding drip-dry properties. Polyester was introduced to the USA as Dacron.

Polyester is made from chemicals extracted from crude oil or natural gas by non-renewable resources and the production of fibers uses large amounts of water for cooling. However, polyester can be seen as an environmentally friendly man-made fabric; if it is not blended it can be melted down and recycled. It can also be made from recycled plastic drinks bottles.

Spandex

Spandex is a super-stretch fiber as it can be stretched 100 per cent and will return to its original length. It was introduced by DuPont in 1959 and is a manufactured elastic fiber; it has similar properties to natural rubber, which is a natural elastic fiber. Spandex is used to add power stretch or comfort to textile products. Power stretch provides garments with holding power and is often used in underwear or swimsuits whereas comfort stretch adds only elasticity.

Aramid fibers

DuPont introduced aramid fibers under the trade name Nome nylon in 1963. The fibre is also known as Kevlar. The fibers have exceptional strength and are five times stronger than steel. They are also flame resistant, decomposing at temperatures of about 371ºC (700ºF). Kevlar is used for strength applications where the fabric needs to be light, for example, in bulletproof outfits. Nome is used for its flameresistance properties especially in military clothing and firefighting uniforms.

New fiber developments

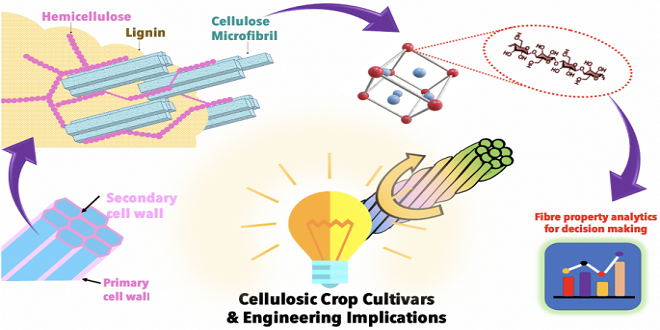

Chemists are now producing fibers from natural sources, changing their structure to produce superior properties. They are also developing microfibres and nanotechnology, which can produce fabrics with advanced properties that can react to the environment in various ways.

Odin Optim

Is a fiber developed by Nippon Keori Kaisha, Ltd in Japan, The Wool mark Company and the Commonwealth Scientific and Industrial Research Organization? They have taken the wool fiber and altered its structure to produce a wool fabric that has superb drape and tactile qualities.

Azlon

This is a generic name for fibers regenerated from milk, peanut, corn and soybean proteins. Japan has produced a fiber made of milk protein and acrylic called Chignon. It resembles silk and is used for garments.

Spider silk or Bios tee

Spider silk is naturally stronger than steel and is stretchy and waterproof. Biochemists are currently studying its structure and developing synthesized fibers with the same properties that could be used for fabric production. It is derived from protein in goat’s milk and is trademarked Bio Steel.

PLA fiber

This is a fire that started being developed in 2001 under the trade name Nature Works. It is derived from naturally occurring sugars in corn and sugar beet. The fiber is produced from a renewable source, needs little energy in production and is recyclable.

Last Word

Microfibers can be produced with microcapsules that contain chemicals such as medication, vitamins, moisturizers, antibacterial agents, UV blockers or perfume. Chemicals in the microcapsules can be released on to the skin either by abrasion or as a result of heat given off by the body. Medication, vitamins or moisturizers can then be absorbed, imparting their benefits to the skin. However, these chemicals do get used up and gradually wash out of the fabric. Micro-organisms can also be incorporated that live off dirt and sweat, therefore maintaining cleaner odor-free garments.